Grundig TK 8

The Grundig TK 8 is the big brother of the TK 7. It is however somewhat larger and therefore also 18 coils can take up. Like the TK 7, the TK 8 also runs with two belt speeds (9.5 and 19 centimeters per second). Apart from that, it almost is the same tape recorder as the TK 5 and the TK 7 from both the set-up and the operation. The TK 8 is, of course, slightly wider due to the larger coils. Also the winding plates had to be installed a little further apart, in order to be able to accommodate the larger coils with an 18 cm diameter. With the large tape reels and the three buttons, the device looks almost like a skull, which is why it has this nickname.

As with the other two models of this range, the front cover can be removed to clean the tape guides and the heads. By this device, this was also urgently needed. All tape guides and, of course, the audio heads were equipped with a thick layer of band abrasion from the last decades, which had to be removed first.

Above all the pressure roller had to be thoroughly cleaned. It is round-brown dyed. But this layer could be removed with some cleaning liquid (isopropanol alcohol) and some cleaning wipes. The pressure felts for the sound heads looked even better, since they touch only the back of the tape.

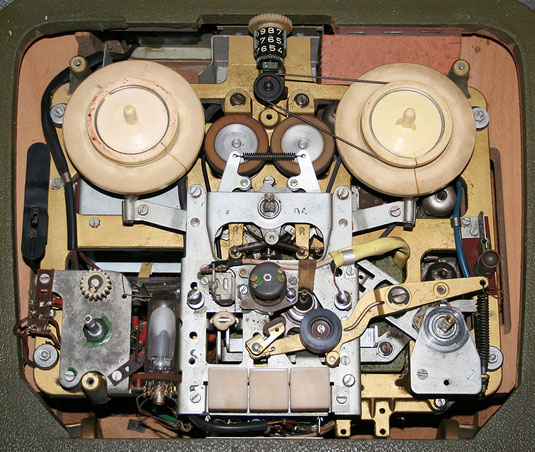

Under the hood one can see the slightly modified design of the TK 8 opposite the TK 5 or the TK 7. Except for a few details the construction is similar to that of the other two devices. The left-hand drive belt for the high-speed running has torn. The right drive belt for the belt disc or tape winding disc surprisingly is still in order.

If you look more closely or compare this drive with those of the other two device types, the TK 8 has slightly larger tape winding discs. The diameters had to be somewhat larger, since the coil reels are a bit further apart and still should be driven by the intermediate wheels. Unfortunately, the plastic wheels are broken in one place, as can be seen clearly in the picture. In the case of the left-hand tape winding disc, the trident is also worn out, so that a reel can not be driven during rapid rewinding and the left disc does not run during tape recording and playback. How such a thing can happen is a mystery to me. However, I have now replaced the tape winding disc with one of a defective TK 23, which can also be used here.

The drive belt for the belt counter is not made of rubber but of a metal spring.In the picture here you can not see so well.

Thus the drive of the TK 8 looks disassembled, when different parts like the head carrier, the tape plates as well as some parts of the mechanics were removed. Again, the similar design of the chassis becomes clear. The left drive belt for the high-speed run and the remaining components has already been removed. I cleaned the mechanical parts and added new lubricants. The drive belts I have ordered and renewed.

Some of the infamous WIMA capacitors (WIMA chocolate bonbons) are located between the drive chassis and the electronics module. One of these capacitors can be seen in the picture. By the way, this capacitor was simply cutt off and replaced below the chassis by a new one. In this way, the old and defective component could remain in the device and did not have to be dismounted. The wiring of the new component can be done very quickly and easily on the underside of the device. In the same way you can "replace" the other capacitor, which is also located between the drive and the electronic module and is only very difficult to access. Of course, it must be known which capacitor it is what and for which value (0.25 or 0.5 μF) it has.

The tape recorder and its interior still looks very good. This picture clearly shows the robust design of the device and the suitcase. On the base of the case there are two large openings with corresponding plastic grids, which are necessary for good device ventilation. The tubes in the unit as well as the motor and the power transformer finally generate a lot of heat, which must be dissipated. For this reason, the device should be placed on a level surface for operation so that the ventilation openings are not covered. This is true not only for this device, but for all tape recorders.

There are three loudspeakers in the front area of the tape recorder, which are controlled by a power amplifier equipped with an EL84. Thanks to the three loudspeakers and the voluminous housing made of wood, the unit has a good sound like the TK 7.

Here you can see the dismantled chassis. In the left area one can recognize the already exchanged capacitors. I have replaced all WIMA capacitors, which I discovered in this device. In the front area is the powerful drive motor from the company "Pabst". To the right in front of the mains transformer you can see the tube EL84. After the exchange of the capacitors, I had to recognize however, that the device makes a loud noise. On the capacitors, however, this could no longer lie, since these had already been replaced. After a while, I found out that the function switch was the cause of these noises. Some of the switch contacts were no longer in order.

After I took the chassis out of the case, I found a small feather on the table. This can be seen in the image section at the bottom left. This spring presses down one of the switching contacts so that it can be connected to the corresponding contact surface on the rotary switch. I have marked the appropriate area in the picture. The switch could be repaired later by attaching the switch contact with a soldering point.

On this picture you can see the Grundig TK 8 (left) as well as the Grundig TK 7 in a direct comparison. You can see that the TK8 is nevertheless significantly larger than the TK 7.

The famous WIMA capacitors should always be replaced.